Watch and Movement Business

Strengths of SII

Since SII was established in 1937, we have been striving to achieve time accuracy, durability, compactness and thinness, and user-friendliness, and we have left brilliant footprints in the history of watches, such as the development of the world’s first quartz watch mounted with a CMOS IC in 1970. Now as a manufacturer of luxury mechanical watches and as a maker of quartz movements coupled with our global No. 1 position in terms of production quantities, we are working to uphold tradition and evolve watch technology.

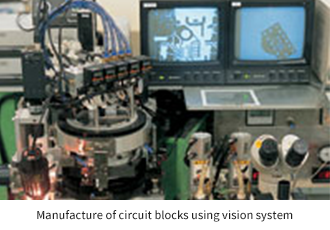

State-of-the-art Automatic Assembly Line

At the watch movement production line in Morioka Seiko Instruments Inc. in Iwate Prefecture, one of our watch production bases, intelligent robots are used in place of humans to assemble parts one by one at high speed at a rate of one piece per second, 24 hours a day. It is not an overstatement to say that this production line, which can flexibly adapt to model changes and increases or reductions in production quantities, is the essence of SII production technology.

|

|

|

|

Integration of Craftsmanship and Advanced Technology

The Shizuku-ishi Watch Studio located in Morioka Seiko Instruments Inc. is a leading Japan-based manufacturer that integrates the full range of manufacturing steps from the making of precision parts such as springs and gears to assembly of finished products. With the advanced parts manufacturing system that utilizes MEMS (Micro Electro Mechanical Systems) and the excellent and delicate techniques of outstanding master watchmakers, the mechanical watches that can be called the pinnacle of the Seiko brand, such as Grand Seiko and Credor, are born here.

|

|

|

|